Adhesion Testing

Adhesion testing is used to evaluate the adhesion to the substrate, in between coats, and internal film. These are verbalized as adhesive and cohesive and are given a number based on the vertical pressure (PSI) at failure.

Tape Adhesion testing

This is the qualitative test of the adhesion coating system. This test will only give allow to ensure there is an adequate bond to the coated substrate. This test does not differentiate between levels of bonding.

Pull-Off Adhesion testing

With the use of a pull-off adhesion tester, we can measure the force required to pull a loading fixture off the surface.

Hire Adhesion Testing Experts

At The Coating Inspector, we pride ourselves on offering comprehensive adhesion testing services to businesses in need of coating inspection. As NACE and AAAMP certified coating inspectors, we specialize in inspecting and protecting industrial and commercial equipment against corrosion. We understand that reliable adhesion is crucial in ensuring the longevity and performance of protective coatings, which is why our team of experts is dedicated to providing the highest quality services in the industry.

When you work with us, you can expect a thorough assessment of your protective coatings. We begin by conducting a detailed visual inspection to identify any signs of coating failure or potential issues. This helps us determine whether the adhesion between the coating and substrate is adequate, or if additional testing is necessary.

One of the primary methods we use for adhesion testing is the pull-off adhesion test. This test involves attaching a small, flat dolly to the surface of the coating and then applying a tensile force using a specialized testing device. The force is gradually increased until the dolly is pulled away from the surface, indicating the adhesion strength of the coating. By measuring the amount of force required to separate the dolly from the surface, we can determine whether the adhesion meets industry standards and client specifications.

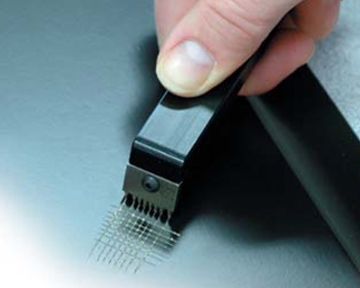

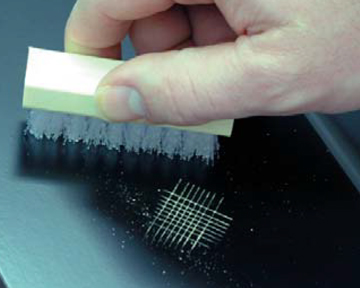

Another common method we employ is the cross-cut or cross-hatch test. In this test, we make several cuts through the coating, down to the substrate, in a grid pattern. We then apply a pressure-sensitive tape to the cut area, and upon removal, we assess the degree of coating detachment. This provides valuable insight into the coating’s adhesion performance and helps us identify any areas of concern.

In addition to these standard tests, our experienced inspectors can also recommend and perform other specialized adhesion testing methods, depending on your unique project requirements. Our ultimate goal is to ensure that your protective coatings are adhering properly to the substrate, providing the best possible protection against corrosion and damage.

Throughout the entire adhesion testing process, our team adheres to strict safety protocols and industry standards. We work diligently to minimize any disruption to your business operations while providing you with accurate, reliable results. Our commitment to quality ensures that you receive a comprehensive evaluation of your coating system’s performance.

By partnering with The Coating Inspector for your adhesion testing needs, you are investing in the longevity and integrity of your equipment. Our skilled team, backed by NACE and AAAMP certifications, offers unmatched expertise and a deep understanding of the factors that contribute to successful coating performance. Our meticulous approach to adhesion testing ensures that potential issues are detected and addressed before they become costly problems.

Don’t leave the protection of your valuable assets to chance. Trust the experts at The Coating Inspector to provide you with the accurate, reliable adhesion testing services your business deserves. Contact us to learn more about how we can help safeguard your equipment against corrosion and ensure the lasting performance of your protective coatings.